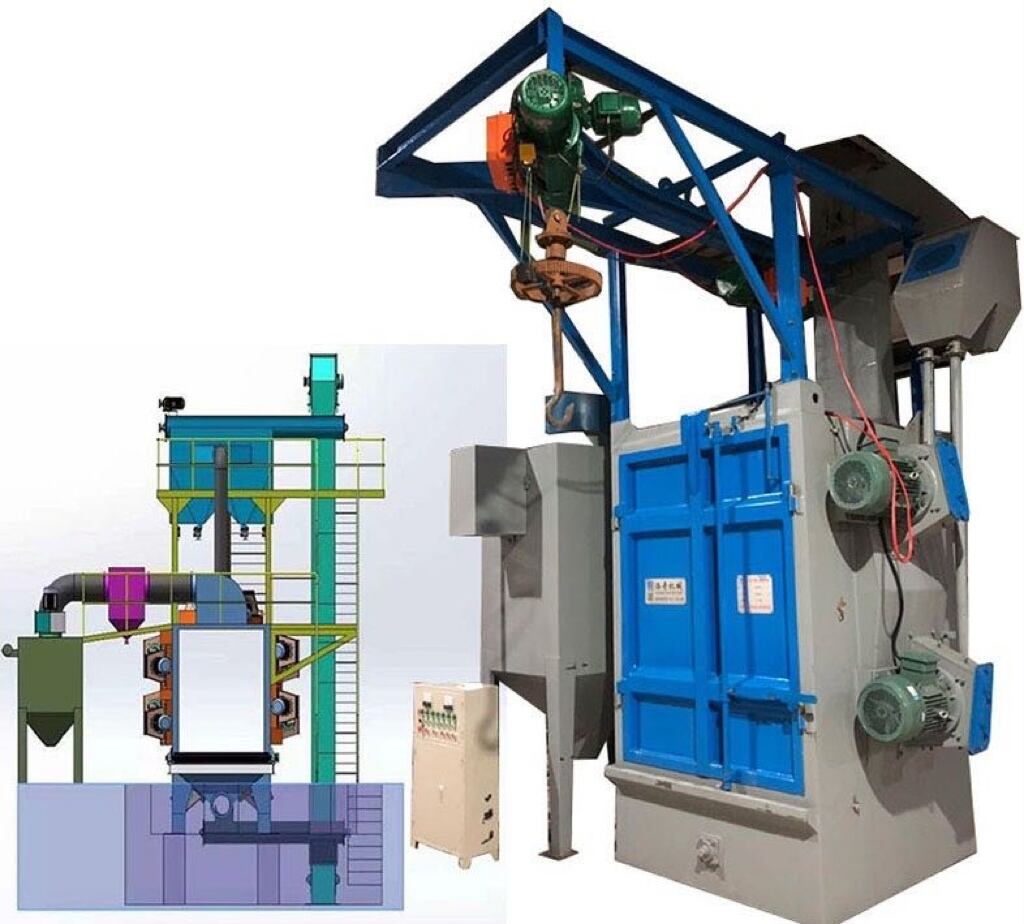

The hook-type shot blasting machine is available in both single hook and double hook configurations

- Overview

- Related Products

Hook type shot blasting machine is mainly used for steel structural parts, castings, aluminum alloy parts and other parts of the surface cleaning and strengthening, widely used in casting, forging, machinery, steel and other industries. It has the characteristics of no pit, compact structure and high productivity.

Hook type shot blasting machine by two hook load workpiece alternately into the shot blasting cleaning room. Use the shot blasting device to throw 0. 2~0. 8 projectiles to the surface of the workpiece, so that the surface of the workpiece reaches a certain roughness, so that the workpiece becomes beautiful, or change the compressive stress of the workpiece to improve the life. This machine is widely used in casting, construction, chemical industry, motor, machine tool and other industries of medium and small casting, forging surface cleaning or strengthening treatment. And this model is suitable for the cleaning of slender and thin wall parts that are not suitable for collision. Hook type shot blasting machine as a standard model of shot blasting machine, its working cylinder diameter from 900 to 1300 mm, height from 1300 to 2200 mm. The standard model has 2-7 throwing heads, the production efficiency of this shot blasting machine is quite high, the flexibility span is also quite large, is the ideal cleaning and strengthening equipment, and the operation is simple, only the workpiece to be processed is loaded on the machine, press the start button, after a very short time (generally 5-7 minutes), that is, the entire cleaning process is completed. Remove all dust and residual pellets, mainly suitable for a variety of medium and large castings, forgings, weldparts, heat treatment of the surface treatment, including fragile and irregular shape of the workpiece.

structure

The hook type shot blasting machine is a hook type cleaning equipment, which is composed of a shot blasting room, a hoist, a separator, a screw conveyor, two shot blasting assemblies, a projectile control system, a hook walking track, a hook system, a rotation device, a foundation, a dust removal system and an electrical control part.

The shot blasting cleaning chamber is composed of a chamber body and a protective plate. The dust removal port is arranged on the rear side wall. The shell of shot blasting cleaning room is a steel plate and welded steel structure, which is a sealed and spacious operating space for shot blasting cleaning of the workpiece. Two sets of QX130 shot blasting assembly are installed on one side wall of the shot blasting chamber to ensure a comprehensive shot blasting cleaning of the cleaned workpiece. The area directly thrown by the shot blasting machine in the chamber is lined with imported rolled Mn13 guard plate with a thickness of 12mm, and the service life of a single shift can reach ten years. Other areas are protected by 65Mn plates. The protection plates are pressed tightly with protective nuts, which is easy to disassemble and replace when necessary. The lower part of the chamber is formed by a beveled edge of the steel plate to form a funnel so that the projectile flows into the spiral conveyor at the bottom. The steel plate is also covered with protective plates. Above the screw conveyor, a steel leakage plate is laid, and a wear-resistant rubber plate is laid above the leakage plate. When used, the wear-resistant rubber plate should be laid in front of the shot blasting machine to protect the steel leakage plate below and extend its service life. The standard configuration of this machine is manual manual opening and closing mode. The machine is designed to open the door. The inside of the door is covered with wear-resistant rubber protection plate, which is pressed by steel pressing plate and hexagonal special nut. There are foam rubber strips around the door to effectively seal around the door; A small part of the pellets brought out when opening the door are put into the chamber to prevent the pellets from falling to the ground and causing people to slip and get injured. An oil cup is provided on the door shaft of the door to lubricate the bearing in the door leaflet regularly.

The shot blasting machine is mainly composed of impeller, blade, shot splitting wheel, directional sleeve, cover shell, protection plate, spindle, shot tube and other parts. The QX130 cantilever centrifugal shot blasting equipment used in this machine has the advantages of high efficiency, convenient installation and maintenance, small space, and can rotate left and right. In the process of rapid rotation, the blade is fixed by the action of centrifugal force, without any fixed fixture. When removing the blade, the blade can be removed by tapping the outer end of the blade, and the removal of eight blades takes only 10-20 minutes. In addition, this series of shot blasting device can also check the wear condition of the shot parting wheel and directional sleeve while removing the blade. In addition, the main shaft of the shot blasting device is installed on the cover, and the holes of the fixed main shaft and the directional sleeve on the cover are processed in one time, which reduces the friction of the shot parting wheel on the projectile and cracks the directional sleeve, and greatly improves the shot blasting efficiency. Directional sleeve in the use of the process, should often check the wear of the rectangular window, when the window wear about 5 mm, must turn about 5 mm (according to the direction of impeller rotation), when the window loss of 15 mm or more should be replaced, otherwise the radial scattering Angle of the projectile will increase proportionally, so as to speed up the wear of the plate and reduce the cleaning efficiency.

When adjusting the shot blasting device of the hook type shot blasting machine, attention should be paid to the position of the directional sleeve of the shot blasting device. The projectile ejection should be fully covered on the workpiece to be cleaned, otherwise the cleaning efficiency will be affected.

The position of the window of the orientation sleeve, if necessary, can be coated with black ink on a piece of wood or lay a piece of thick paper, placed on the position of the workpiece to be cleaned, start the shot blasting device, manually add a small amount of projectiles to the shot tube of the shot blasting device, check the position of the ejection belt, such as the location of the ejection area is not correct, should adjust the orientation sleeve to obtain the ideal position.

After the orientation sleeve is adjusted, the load test can be carried out, and after 30 minutes of shot blasting, 400Kg of projectiles can be added.

Bucket elevator is composed of cycloidal pinwheel reducer and frame, upper and lower drum, conveyor belt, hopper, closed barrel and tightening device. The lower end feed port of the bucket elevator is connected with the screw conveyor, and the upper end discharge port is connected with the shot sand separator. Hoist cover adopts welding structure, beautiful appearance and good rigidity. The elevator cover is provided with an access door, which can repair and replace the hopper. Opening the door cover on the lower housing allows the lower drive to be serviced and its bottom shot blocked. The machine adopts flat belt rotation. When working, the hopper fixed on the conveyor belt will scrape the shot material at the bottom of the elevator, and then under the drive of the elevator machine, the shot material is lifted to the top of the elevator, and finally by centrifugal gravity feeding, the shot material is separated into the shot sand. At the same time, the hoist is equipped with a set of tightening device. When the belt is relaxed for a period of time, the belt can be tightened by adjusting the adjustment bolts on both sides of the lifting machine. The adjustment range is 100 mm, and the adjustment amount at both ends should be consistent when adjusting.

| Itms | Units | 0376 | 0378 | 03710 | 03720 | Q3730 | Q3750 | 03780 |

| Single hook hoisting | 18 | 1000 | 1000 | 1000 | 2000 | 3000 | 5000 | 8000 |

| Shot blast ing capacity | kg/min | 2x200 | 2*250 | 2*250 | 3*250 | 3*250 | 4x250 | ■250 |

| Splitter mar separation | I/h | 25 | 30 | 30 | 45 | 45 | 60 | 60 |

| Bucket elevator lifting | T/h | 25 | 30 | 30 | 45 | 45 | 60 | 60 |

| Clean varkpiece size | m | Φ600*1100 | Φ800*1500 | Φ1000*1800 | Φ1400*2300 | Φ1600*2300 | Φ1600*2500 | Φ2000*3000 |

| Total pover | 1 | 22 | 37 | 46 | 61 | 64 | 78 | 81 |