- Overview

- Related Products

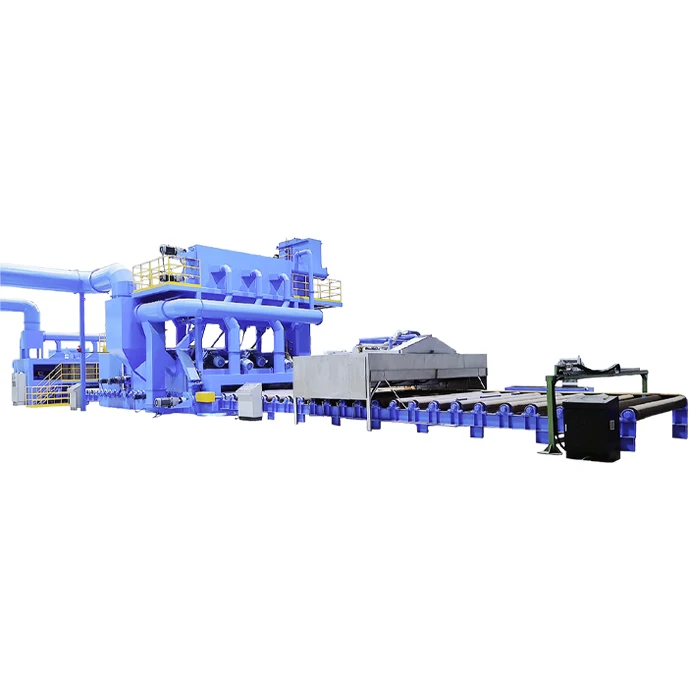

The series of equipment move the workpieces by motor roller, and the workpiece was be shoted by pill from different angle when, go ahead, it is widely used in steel structure, building, bridge, surface treatment of large l-shaped steel, H steel.

It is used for stress relief and surface rust cleaning of large I-shaped steel and H-shaped steel structural parts with higher dimensions. The roller pass through the shot blasting machine. During the cleaning process, the electrically controlled adjustable speed conveying roller will send the steel structure or steel into the body ejecting area of the cleaning machine room. All sides of the body will be hit and rubbed by strong dense projectiles from different coordinate directions, so that the oxide, rust layer and dirt on it will quickly fall off, and the steel surface will obtain a certain roughness of the smooth surface. Import and export roller table loading and unloading parts on both sides of the cleaning room. The pellets and rust dust falling into the steel above are blown by the purging device, and the mixture of pellets and dust falling down is transported by the recovery spiral to the chamber funnel, the vertical and horizontal screw conveyor is collected in the lower part of the elevator, and then lifted to the separator on the upper part of the machine, and the separated pure pellets fall into the separator hopper for shot blasting cycle. The dust generated during shot blasting is sent to the dust removal system by the exhaust pipe, and the net gas after purification is discharged into the atmosphere, and the granular dust is captured and collected

| Model number | QH0808 | QH0612 | QH0816 | QHL018 | QH1525 | |

| WorkpieceDimensi on | Widlh and Heighl (mm) | 600*600 | 400*1000 | 600*1400 | 800*1600 | 1300*2300 |

| Leng Lh(mm) | 3000-12000 | 3000-12000 | 3000-12000 | 3000-12000 | 3000-12000 | |

| BlasLing wheel | BlasLing Capaci Ly(kg/min) | 4*200 | 6*200 | 8*200 | 8*200 | 10*200 |

| Pover (kw) | 4*L1 | 6*LL | 8*L1 | 8*L1 | 10*LL | |

| Roller Lable al lows 1oad (kg/m) | 500 | 500 | 1000 | 1000 | 1500 | |

| Roller conveyor speed(m/min) | 0. 4-4 | 0. 4-4 | 0. 4-4 | 0. 4-4 | 0. 4-4 | |

| VenlilaLion Capacily(㎡/h) | 12000 | 15000 | 18000 | 18000 | 24000 | |

| Pellel malerial circulalion(T/h) | 50 | 70 | 120 | 120 | 150 | |

| Tolal Power (kw) | -70 | ■120 | ■125 | ■130 | ■200 | |