- Overview

- Related Products

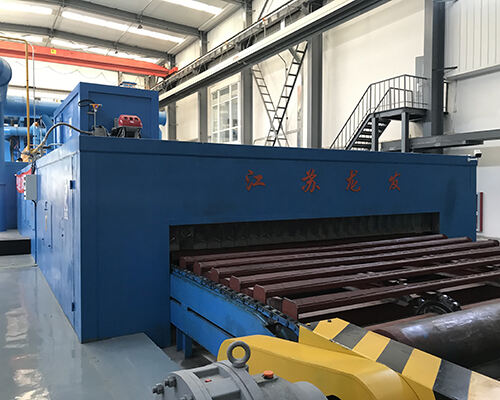

Steel plate shot blasting machine is a kind of multi-functional steel pretreatment line for cleaning welded structural parts, H steel, shaped steel, mesh frame, steel plate, and the treatment of steel plate rust polishing!

Introducing the Steel Plate Shot Blasting Machine - your ultimate solution for steel surface treatment and preparation.

This state-of-the-art machine is designed to meet the diverse needs of industries involved in steel fabrication, construction, and manufacturing.

The Steel Plate Shot Blasting Machine is a versatile and efficient system that offers a comprehensive solution for cleaning, descaling, and surface preparation of a wide range of steel components. Whether it's welded structural parts, H steel, section steel, grids, or steel plates, this machine is capable of delivering exceptional results.

One of the key features of this machine is its ability to remove rust and polish steel plates, ensuring that the treated surfaces are not only clean but also have a smooth and uniform finish. This is essential for ensuring the quality and integrity of the steel components, ultimately leading to improved performance and longevity.

With its advanced shot blasting technology, the machine effectively propels abrasive materials at high velocity to clean and prepare the steel surfaces. This process not only removes contaminants and impurities but also creates a surface profile that enhances the adhesion of coatings, paints, and other surface treatments.

The Steel Plate Shot Blasting Machine is designed for high productivity and efficiency, allowing for rapid processing of steel components without compromising on quality. Its robust construction and reliable performance make it a valuable asset for any industrial operation that requires precision surface treatment of steel materials.

In conclusion, the Steel Plate Shot Blasting Machine is a versatile, reliable, and high-performance solution for all your steel surface treatment needs. Whether you are looking to clean, descale, or polish steel components, this machine is equipped to deliver exceptional results, ensuring that

Introducing the Steel Plate Shot Blasting Machine: Revolutionizing Steel Pretreatment

Are you in the business of manufacturing welded structural parts, H steel, section steel, grids, or steel plates? If so, you understand the importance of ensuring that your steel products are clean, free from rust, and polished to perfection. This is where the Steel Plate Shot Blasting Machine comes into play. This innovative piece of equipment is a game-changer in the steel industry, offering a multi-functional solution for steel pretreatment.

The Steel Plate Shot Blasting Machine is designed to meet the diverse needs of steel manufacturers, providing a comprehensive solution for cleaning, rust removal, and polishing of steel plates. Its versatility and efficiency make it an indispensable tool for enhancing the quality and durability of steel products.

One of the key features of the Steel Plate Shot Blasting Machine is its ability to clean welded structural parts with precision and speed. The machine's advanced technology ensures that even the most intricate and hard-to-reach areas of welded parts are thoroughly cleaned, resulting in a pristine finish that meets the highest industry standards.

In addition to cleaning welded parts, the machine is also highly effective in preparing H steel, section steel, grids, and steel plates for further processing. By removing rust and other surface imperfections, the Steel Plate Shot Blasting Machine ensures that the steel products are primed for subsequent manufacturing processes, saving time and resources in the production line.

Furthermore, the machine's polishing capabilities are a testament to its versatility. With the ability to polish steel plates to a smooth and lustrous finish, the Steel Plate Shot Blasting Machine adds a touch of finesse to the final product, making it stand out in the market and appealing to discerning customers.

The efficiency of the Steel Plate Shot Blasting Machine is another standout feature. With its high output capacity, the machine is capable of handling large volumes of steel products, making it suitable for both small-scale operations and large-scale manufacturing facilities. Its ability to deliver consistent results at a rapid pace ensures that production targets are met without compromising on quality.

Moreover, the machine's user-friendly design and intuitive controls make it easy to operate, minimizing the need for extensive training and allowing operators to maximize their productivity. Its robust construction and durable components also contribute to its reliability, ensuring minimal downtime and maintenance costs.

In conclusion, the Steel Plate Shot Blasting Machine is a game-changing solution for steel pretreatment, offering a comprehensive set of features that cater to the diverse needs of steel manufacturers. From cleaning welded parts to removing rust and polishing steel plates, this machine is a versatile and efficient tool that enhances the quality and marketability of steel products. With its high output capacity, user-friendly design, and exceptional performance, the Steel Plate Shot Blasting Machine is a valuable asset for any steel manufacturing operation, setting new standards for steel pretreatment in the industry.

| The speed ofwheelCO0 r(m/mmh) | 05-4 |

| The hiduness ofdearirgeelshee(mm) | 3-100-44-100 |

| The seclonskelspedtokon(nm) | 200300-4000300 |

| 101TheshololaIng(gmhn) | +'130-8360 |

| The irs lendosednll(kg) | 4000--11000 |

| Roll brushadlusirg50m m) | 200-500 |

| Almesspadtyom 5tu | 22000--30000 |

| Exterkor str | 25014*4500*9015 |

| Todlpowerexcapltordusi dearirO)(W) | 50-253.6 |

| Roller corue yor speed m | umlr | 05-40 | 0540 | 05-50 | 10-50 | 10-50 | 10-50 | 1050 | 1050 | |

| 5 | Thidkress ofplat | mm | 子 | 子6 | 子 | 子 | 3印 | 360 | ||

| 6 | Processing protie spe d | icat | ors | S20# | s20# | ■25# | ■25# | s2S# | ||

| Abrasue uolume | 0ml | 6.30 | ||||||||

| 3 | Flrstloeng qunlyo | kg | 4000 | 4000 | 4000 | *500 | *50D | 3000 | ||

| 9 | Brush regualng heghi | mm | 200 | 350 | *50 | 450 | *50 | |||

| 10 | Venita lon | m■ | 12000 | 17560 | 19000 | 25000 | 20000 | 00000 | ||

| 환 | kw | =157 | =305 | =225 |