- Overview

- Series

- Related Products

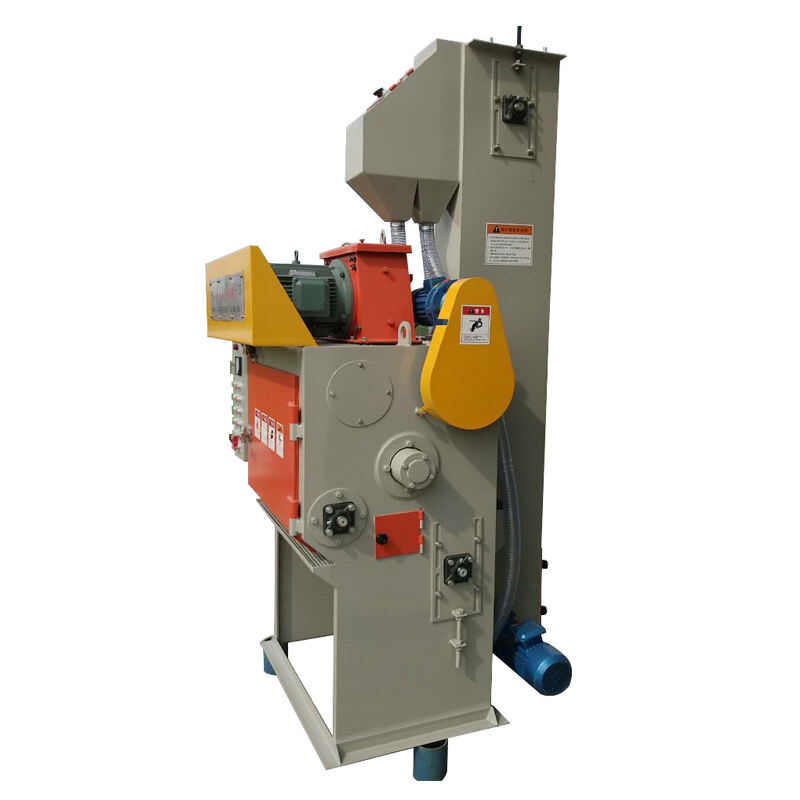

The caterpillar shot blasting machine is a high-strength wear-resistant rubber track or manganese steel track loading workpiece. It uses a high-speed rotating impeller to throw the projectile to the workpiece in the chamber to achieve the purpose of cleaning. It is suitable for small castings, forgings, stamping parts, gears, springs and other parts of sand cleaning, rust removal, removal of oxide and surface strengthening, especially suitable for not afraid of collision parts cleaning and strengthening.

The caterpillar shot blasting machine is a high-strength wear-resistant rubber track or manganese steel track loading workpiece. It uses a high-speed rotating impeller to throw the projectile to the workpiece in the chamber to achieve the purpose of cleaning. It is suitable for small castings, forgings, stamping parts, gears, springs and other parts of sand cleaning, rust removal, removal of oxide and surface strengthening, especially suitable for not afraid of collision parts cleaning and strengthening.

This machine is a comprehensive domestic and foreign technology, is a good cleaning effect, compact structure, low noise, cleaning equipment, used in large and medium-sized batch production of surface rust or shot blasting strengthening, has the following characteristics:

1, the use of cantilever centrifugal shot blasting, with long service life, simple structure and other characteristics;

2, the use of 75 m/s, 80 m/s, 85 m/s three kinds of projectile speed.

3, the pulley adopts the international advanced quick change structure, which is conducive to improving production efficiency and reducing labor intensity.

4, the use of BE separator, with good separation effect and high productivity, has a positive effect on improving the life of the blade;

5, the use of bag dust collector, dust emission concentration is lower than the national standard, improve the working environment of workers;

6. This model has added some special mechanisms such as manual shot parting gate and discharge door.

7, the model of the crawler type shot blasting machine can be used alone, but also can be wired to use structure and principle This machine is a small cleaning equipment, mainly by cleaning room, shot blasting assembly, elevator, separator, electrical system and other parts.

Working principle: Add a specified number of workpieces in the cleaning chamber, after the machine starts, the projectile thrown by the shot blasting machine at high speed forms a flow shot bundle, and evenly hits the surface of the workpiece, so as to achieve the purpose of cleaning and strengthening. The thrown projectiles and sand particles flow into the elevator and are lifted by the elevator into the separator for separation. The dust is sucked into the dust collector by the fan, and the clean air is discharged into the atmosphere. The dust on the cloth bag falls into the dust collection box at the bottom of the dust collector by mechanical vibration, and the user can remove it regularly. The waste sand is discharged from the waste pipe, and the user can reuse it. The shot sand mixture is collected into the chamber by the recycling pipe, and then reused after separation by the separator. The clean projectile enters the application range of the shot blasting machine by the electromagnetic shot supply gate. The crawler shot blasting machine is suitable for cleaning the surface of various parts. All kinds of metal castings surface sand cleaning, black metal parts surface rust removal, stamping parts surface and burr blunt, forging and burr heat treatment of the workpiece surface treatment and spring surface oxide removal and surface refinement can be achieved by the series of equipment shot blasting process.

Its application range is very wide, mainly has the foundry, thermal treatment plant, motor factory, machine tool parts factory, bicycle parts factory, power machine factory, automobile parts factory, motorcycle parts factory, non-ferrous metal die casting factory. The workpiece after shot blasting can obtain a good material color, and can also become the first process of the metal parts surface blackening, blue, passivation and other processes, and can provide a good base for electroplating, painting and finishing. After shot blasting, the tensile stress of the workpiece can be reduced, and the surface grain can be refined, so as to strengthen the surface of the workpiece and increase its service life.

| Type | 0324 | 0326 | 0328 | 03210 | 03210 IAutoaatic loading and udloadicg) |

| Productmt/ | 0. 3-0. 6 | 0. 6-1. 2 | 1. 2-2. 0 | 2. 0-2. 8 | 2. 0-2. 8 |

| Har Teight eacb prece (ad) | 5 | 10 | 15 | 25 | 25 |

| Plate daseter (ma) | 400 | 650 | 800 | 1000 | 1000 |

| Effectire capacity(a') | 0. 05 | 0. 15 | 0. 2 | 0. 3 | 0. 3 |

| Ball-blantiog ooaDtity(/un) | 40 | 150 | 150 | 250 | 250 |

| AIT volume fordut carcber (m3/b) | 2000 | 2200 | 2600 | 3500 | 3500 |

| otal somer lkwl | ~6 | -13 | 19 | -21 | -26 |