- Overview

- Related Products

Items | Q376 | Q378 | Q3710 | Q3720 | Q3730 | Q3750 | Q3780 |

Single hook hoisting(kg) | 1000 | 1000 | 1000 | 2000 | 3000 | 5000 | 8000 |

Shot blasting capacity(kg/min) | 2*200 | 2*250 | 2*250 | 3*250 | 3*250 | 4*250 | 4*250 |

Splitter max separation volume(T/h) | 25 | 30 | 30 | 45 | 45 | 60 | 60 |

Bucket elevator lifting capacity(T/h) | 25 | 30 | 30 | 45 | 45 | 60 | 60 |

Clean workpiece size(mm) | φ600*1100 | φ800*1500 | φ1000*1800 | φ1400*2300 | φ1600*2300 | φ1600*2500 | φ2000*3000 |

Total power(kw) | 22 | 37 | 46 | 61 | 64 | 78 | 81 |

1. How to install the machine? Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2 engineers to guide the installation and assembly of non-standard equipment at your factory.

2. Do you sell steel shot or steel grit which can be uses in shot blasting machine? We can provide products such as steel shot, steel sand, steel wire cutting shot, stainless steel shot, and other metal abrasives related to surface cleaning and anti corrosion.

3. How long is your delivery time? Generally Standard shot blasting machine 7-20 workdays. Non Standard Shot blasting machine is 20-60 workdays. Shot peening machine is

30-60 workdays. It is according to quantity and machine model.

4. What is the shot blasting machine? Shot blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, ship building rail, and many others.

5. What are your pre-sales and after sales services? Pre sales services include: consulting products, samples, technical solutions and quota tions; After sales service includes: 24-hour response, engineers' online guidance, engineers' installation in the customer's factory, and training on how to install and use the product

Longfa

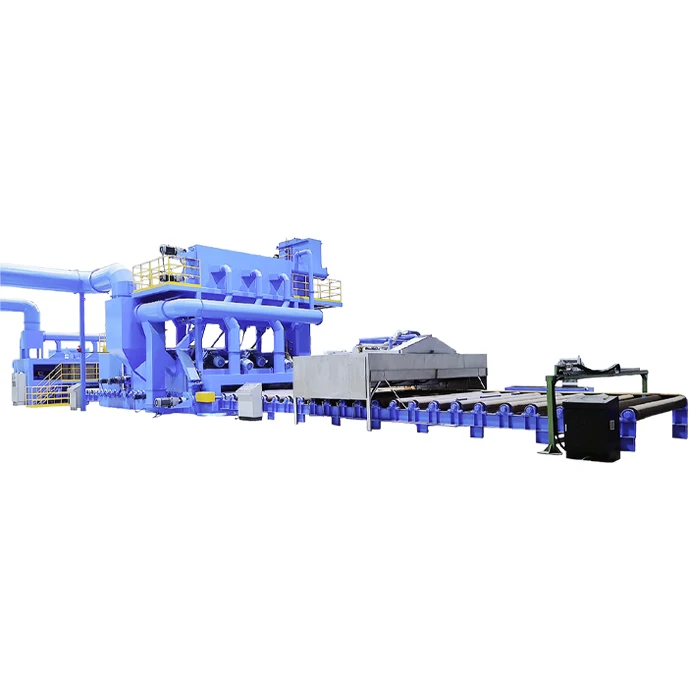

Introducing the Whole Sale Automatic Metal Surface Hook Shot Blasting Machine the ultimate solution cleansing steel surfaces with ease and effectiveness.

Built to eliminate rust other impurities from steel surfaces. An ideal device for production and metalworking businesses that need accuracy and quality.

Features an engine powerful which drives the metal shot at high velocity impacting and cleaning the material treated. Its robust construction ensures durability and longevity.

Convenient to make use of for cleansing large and metal firms a hook loading system. Perfect for mass production. The Longfa fully enclosed framework ensures security when it comes to operator the environment.

Controlled by PLC ensures that lots of components of the item are washed evenly without room for mistake. Perfect for large-scale production such as automotive aerospace and shipbuilding.

Incredibly efficient. Separates dirt along with other impurities from the steel. The look of the dirt collector allows maintenance this is easy cleansing as the automatic blow-off system ensures operation is continuous.

Intended to deliver performance maximum terms of speed effectiveness and quality. This represents the technology latest in shot blasting and sets a brand name new standard commercial cleaning.

A dependable and solution this is economical all cleaning requires with Longfa's several years of experience and expertise. Best for companies wanting to enhance their efficiency and quality of work.

Perfect your businesses and will help bring your operations to another location levels.