- Overview

- Related Products

Model number | Q6910 | Q6920 | Q6925 | Q6930 | Q6940 | Q6950 |

Cleaning size (mm) longxwide | 12000 (L) x1000 (W) thick: 6-60H: 500 | 12000 (L) X 2500 (W) thick: 6-60 H: 400 | 12000 (L) X 2500 (W) thick: 6-25 H: 400 | 12000 (L) X 3000 (w) thick: 6-60 H: 400 | 12000 (L) X 4000 (w) thick: 6-60 H: 400 | 12000 (L) X 5000 (w) thick: 6-60 H: 400 |

Running speed of roller table (m/min) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Feed roller length (mm) | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Effective working width (mm) | 1300 | 2300 | 2800 | 3300 | 4300 | 5300 |

Discharge roller length (mm) | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Dust removal fan power (kw) | 15 | 18.5 | 22 | 37 | 45 | 55 |

Number of blast devices (Taiwan) | 4 | 6 | 6 | 8 | 10 | 10 |

Shot blast power (kw) | 11X4 | 15X6 | 18.5X6 | 22X8 | 22X10 | 30X10 |

Shot blasting quantity (kg/min) | 250X4 | 270X6 | 290X6 | 340X8 | 340X10 | 400X10 |

Hoist power (kw) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

Lifting capacity (t/h) | 60 | 90 | 140 | 180 | 225 | 260 |

Separator power (kw) | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 |

Separated dose (t/h) | 60 | 90 | 144 | 120 | 170 | 170 |

Gross power (kw) | ≈86 | ≈153 | ≈189 | ≈280 | ≈350 | ≈454 |

Jiangsu Longfa Blast Machine Co. Ltd

1. How to install the machine? Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2engineers to guide the installation and assembly of non-standard equipment at your factory

2. Do you sell steel shot or steel grit which can be uses in shot blasting machine? We can provide products such as steel shot, steel sand, steel wire cutting shot, stainless steel shot, and other metal abrasives related to surface cleaning and anti corrosion

3. How long is your delivery time? Generally Standard shot blasting machine 7-20 workdays. Non Standard Shot blasting machine is 20-60 workdays. Shot peening machine is 30-60 workdays. It is according to quantity and machine model

4. What is the shot blasting machine? Shot blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, ship building rail, and many others

5. What are your pre-sales and after sales services? Pre sales services include: consulting products, samples, technical solutions and quota tions; After sales service includes: 24-hour response, engineers' online guidance, engineers' installation in the customer's factory, and training on how to install and use the product

Longfa

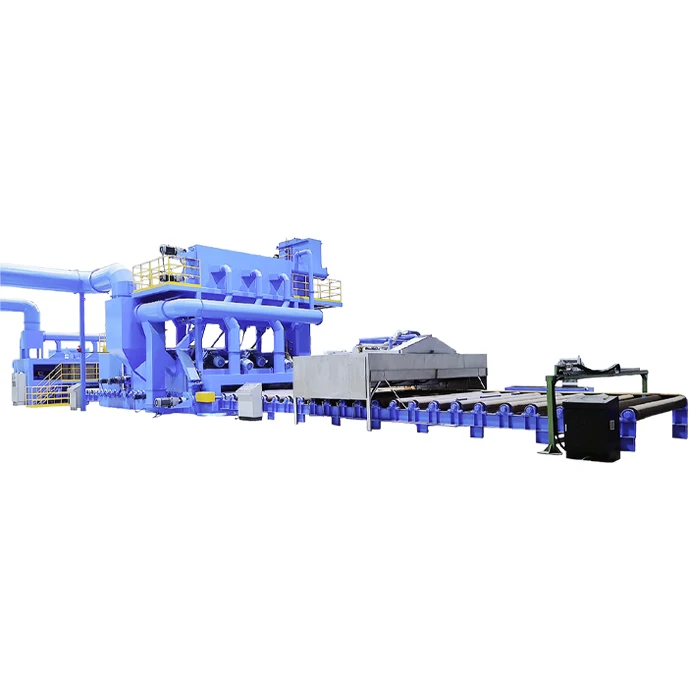

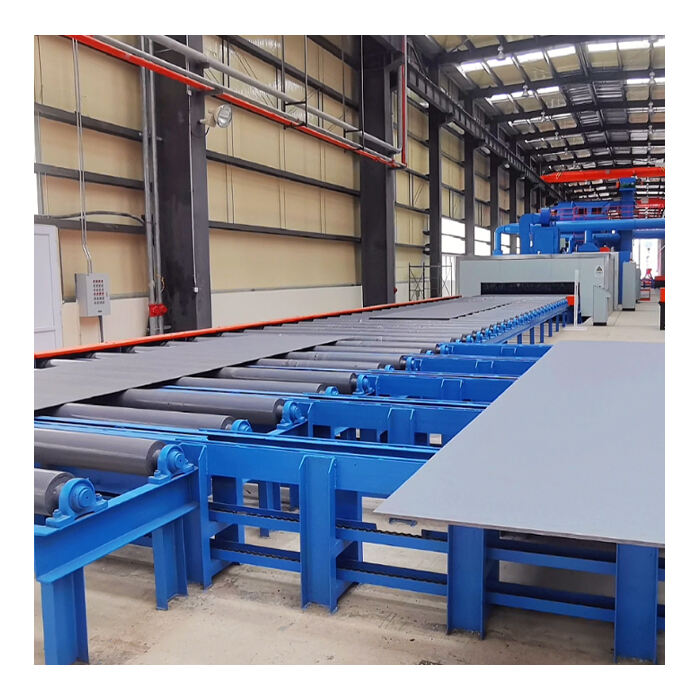

Introducing the Laser Rust Removal Steel Plate Shot Blasting Machine For Polishing, the latest technology in steel plate maintenance. Utilizes lasers to get rid of rust and impurities from steel dishes leaving them looking polished and clean. A game-changer for those within the metal fabrication industry. With advanced level laser technology it's with the capacity of removing rust scale and other surface impurities efficiently. Designed to the office on steel dishes of different thicknesses and sizes. It's ideal for used in large settings that are commercial as shipyards steel mills pipeline construction sites and metal fabrication workshops. Boasts a cutting-edge design that is both effective and efficient. The laser technology targets the rust and impurities on the surface of the metal plate penetrating deep to remove even the rust that is toughest and grime. Not only effective when it comes to rust and impurity removal but it's also energy-efficient. Combines laser that is high-powered with an automated blaster system that works to get rid of rust and impurities without wasting energy. Easy to use even if you are not familiar aided by the technology that is latest in the rust removal process. Has user-friendly controls so anyone can operate it with ease. Get yourself a Longfa Laser Rust Removal Steel Plate Shot Blasting Machine today.