- Overview

- Related Products

Items |

Q376 |

Q378 |

Q3710 |

Q3720 |

Q3730 |

Q3750 |

Q3780 |

Single hook hoisting(kg) |

1000 |

1000 |

1000 |

2000 |

3000 |

5000 |

8000 |

Shot blasting capacity(kg/min) |

2*200 |

2*250 |

2*250 |

3*250 |

3*250 |

4*250 |

4*250 |

Splitter max separation volume(T/h) |

25 |

30 |

30 |

45 |

45 |

60 |

60 |

Bucket elevator lifting capacity(T/h) |

25 |

30 |

30 |

45 |

45 |

60 |

60 |

Clean workpiece size(mm) |

φ600*1100 |

φ800*1500 |

φ1000*1800 |

φ1400*2300 |

φ1600*2300 |

φ1600*2500 |

φ2000*3000 |

Total power(kw) |

22 |

37 |

46 |

61 |

64 |

78 |

81 |

1. How to install the machine? Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2 engineers to guide the installation and assembly of non-standard equipment at your factory.

2. Do you sell steel shot or steel grit which can be uses in shot blasting machine? We can provide products such as steel shot, steel sand, steel wire cutting shot, stainless steel shot, and other metal abrasives related to surface cleaning and anti corrosion.

3. How long is your delivery time? Generally Standard shot blasting machine 7-20 workdays. Non Standard Shot blasting machine is 20-60 workdays. Shot peening machine is

30-60 workdays. It is according to quantity and machine model.

4. What is the shot blasting machine? Shot blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, ship building rail, and many others.

5. What are your pre-sales and after sales services? Pre sales services include: consulting products, samples, technical solutions and quota tions; After sales service includes: 24-hour response, engineers' online guidance, engineers' installation in the customer's factory, and training on how to install and use the product

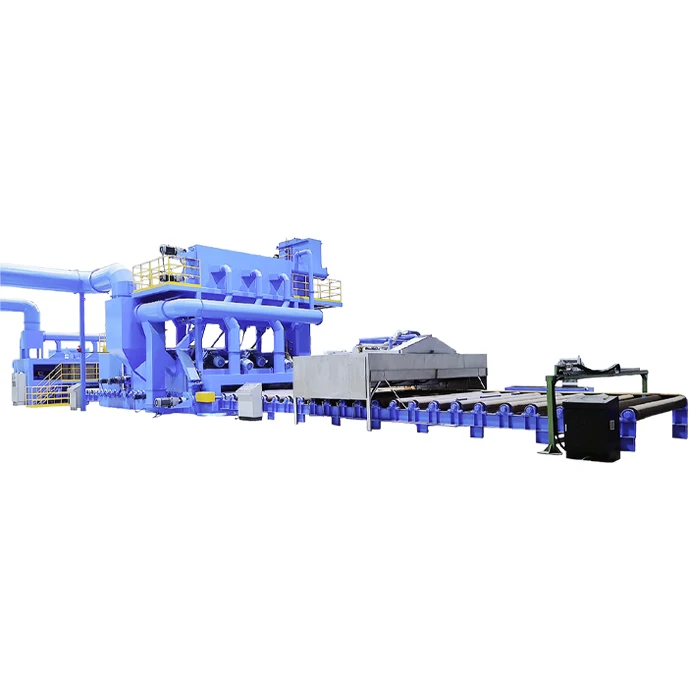

Longfa

Proud to present its best-selling automatic industry abrasive hook shot blasting machine for casting and forging surface cleaning.

Having a processing capacity all the way to 1200 kg/h this is designed to handle perhaps the cleaning toughest jobs efficiently and effortlessly.

Includes a durable and design is robust assures and reliability. Its motor this is powerful ensures speedy and cleaning is beneficial while its compact size and easy-to-use settings allow it to be suitable for found in an extensive array of industrial settings.

The utilizes shot is technology this is abrasive completely clean casting and forging surfaces efficiently. Abrasive blasting Longfa is a technique that needs making use of is compressed propel abrasive particles against an area. Effortlessly removes area contaminants such as rust paint and scale leaving the utmost effective ready and clean for further processing.

Equipped with various features making it stand down off their shot devices which may be blasting the marketplace. for example, this has a loading is automatic system this is unloading permits uninterrupted operation and saves time. Features a dust is special system guarantees on a clean working environment and protects employee’s health.

User-friendly that enables operators to regulate the parameters to support often applications specific. Having its electronic display operators can monitor the equipment's performance and work out necessary adjustments get cleansing is optimal.

Built to meet up utilizing the high criteria associated with industry and casting is forging. Its robust construction exceptional performance and easy-to-use features help it become a reliable option both small and large-scale commercial applications.

Buy this today and be amazed.