- Overview

- Related Products

Model number | Q6910 | Q6920 | Q6925 | Q6930 | Q6940 | Q6950 |

Cleaning size (mm) longxwide | 12000 (L) x1000 (W) thick: 6-60H: 500 | 12000 (L) X 2500(W) thick: 6-60 H: 400 | 12000 (L) X 2500(W) thick: 6-25 H: 400 | 12000 (L) X 3000 (w) thick: 6-60 H: 400 | 12000 (L) X 4000 (w) thick: 6-60 H: 400 | 12000 (L) X 5000 (w) thick: 6-60 H: 400 |

Running speed of roller table (m/min) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Feed roller length mm | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Effective working width mm | 1300 | 2300 | 2800 | 3300 | 4300 | 5300 |

Discharge roller length mm | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Dust removal fan power (kw) | 15 | 18.5 | 22 | 37 | 45 | 55 |

Number of blast devices (Taiwan) | 4 | 6 | 6 | 8 | 10 | 10 |

Shot blast power (kw) | 11X4 | 15X6 | 18.5X6 | 22X8 | 22X10 | 30X10 |

Shot blasting quantity (kg/min) | 250X4 | 270X6 | 290X6 | 340X8 | 340X10 | 400X10 |

Hoist power (kw) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

Lifting capacity (t/h) | 60 | 90 | 140 | 180 | 225 | 260 |

Separator power (kw) | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 |

Separated dose (t/h) | 60 | 90 | 144 | 120 | 170 | 170 |

Gross power (kw) | ≈86 | ≈153 | ≈189 | ≈280 | ≈350 | ≈454 |

Jiangsu Longfa Blast Machine Co. Ltd

The Company has forged solid and stable partnerships with numerous renowned domestic and international brand enterprises, steadily cultivating significant advantages in talent, technology, and branding. The Company boasts a registered capital of RMB 60 million and employs 120 staff members, of which 40 are scientific and technical personnel. Currently, the Company spans approximately 120 mu, with a constructed area of 20, 000 square meters

1. How to install the machine? Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2engineers to guide the installation and assembly of non-standard equipment at your factory

2. Do you sell steel shot or steel grit which can be uses in shot blasting machine? We can provide products such as steel shot, steel sand, steel wire cutting shot, stainless steel shot, and other metal abrasives related to surface cleaning and anti corrosion

3. How long is your delivery time? Generally Standard shot blasting machine 7-20 workdays. Non Standard Shot blasting machine is 20-60 workdays. Shot peening machine is 30-60 workdays. It is according to quantity and machine model

4. What is the shot blasting machine? Shot blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, ship building rail, and many others

5. What are your pre-sales and after sales services? Pre sales services include: consulting products, samples, technical solutions and quota tions; After sales service includes: 24-hour response, engineers' online guidance, engineers' installation in the customer's factory, and training on how to install and use the product

Longfa

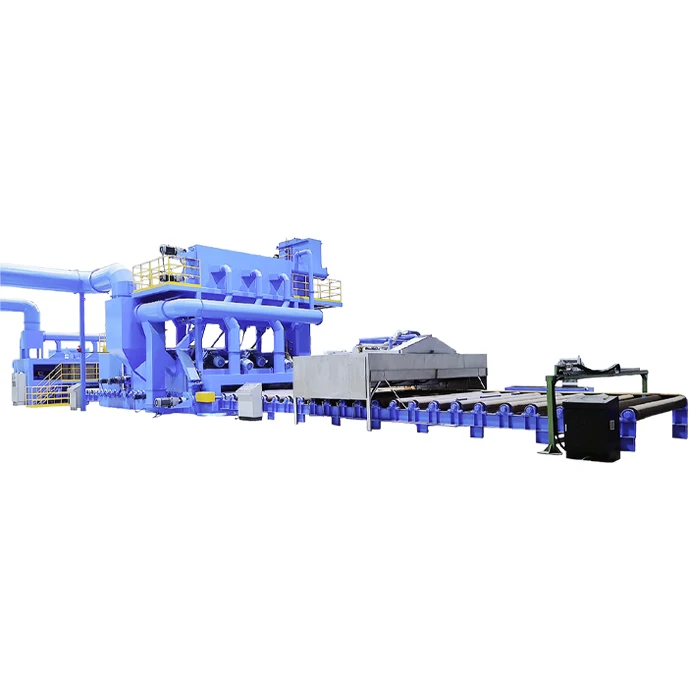

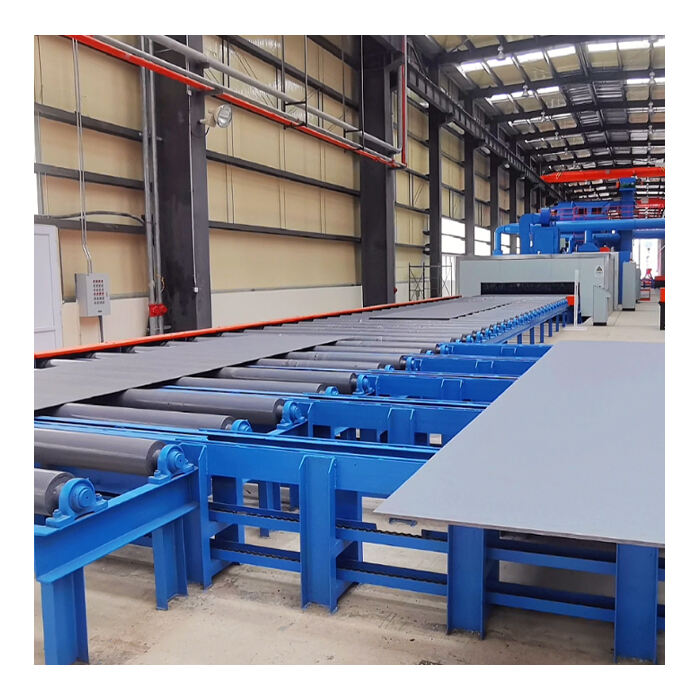

Laser Rust Removal and Shot Blasting Machine - an advanced product from Longfa is the perfect solution for the quick and efficient removal of rust and paint from steel plates and other surfaces. This cheap product has revolutionized the rust and paint removal process in the steel industry. The combination of laser technology and shot blasting proves to be more effective than traditional methods and makes work easier for users. Design is compact is straightforward to utilize - with only a few steps necessary to clean the surface of any steel material. The laser is directed at first glance while the light absorbed by the paint and rust converts to heat power that vaporizes the rust and paint. The shot blasting process then removes the rust is vaporized paint from the metal surface and prepares it for further processing or usage. A low-cost high-quality product that saves time, energy, and money for users. Its advanced technology such as the laser system and shot blasting engine are carefully designed to make certain efficiency is maximum quality. The product boasts of the level is high of letting you clean only the rust and paint without damaging the metal surface. This saves time and money by limiting the need for extra repair or maintenance after cleansing. The removal process is also green - no chemical substances or solvents are used which means that you don't need to worry about hazardous waste disposal. The laser technology guarantees a clean rust-free surface that will be painted or coated with minimal preparation. Suited to many different industrial and applications which are commercial. It is perfect for automotive construction shipbuilding and industries being manufacturing require rust and paint treatment from steel plates, iron pipes, along with other steel surfaces. With an affordable price range and easy installation features the Longfa Laser Rust Removal and Shot Blasting Machine is a must-have for anyone in the metal fabrication industry. The product is built to last and offers a reliable, quick, and efficient rust and paint removal solution that saves time energy and money. Unlike other rust removal methods this product is a one-time investment that is worth every penny spent.