I wonder, though, who ever thought machines could clean giant things like bridges, ships, and buildings? Sounds like a pretty rough gig, sure? One such method is Concrete shot blasting nozzles. Shot blasting nozzles blow out small pieces of metal, known as shot, to create the blasting effect. They blast these small chunks with powerful air to propel them at high velocities. Sure, this will help rinse away dirt, paint, and rust that may build up on the surfaces. There are a variety of different shot blasting nozzles on the market, and following in this guide, we are going to learn why shot blasting nozzles are significant, how to select the suitable shot blasting nozzle to suit your needs and the advantages of using a quality shot blasting nozzle.

There are certain factors which are extremely important and need to be considered when choosing a Longfa shot blasting nozzle. To begin, you have to take a look at the size of a nozzle. The short blast machine size matters because using the nozzle means using a certain amount of air. This can affect the pressure and speed of the resultant shot. Then, look at the shape of the nozzle. It will determine how the shot disperses when fired. When you expect the best cleaning, you have to keep the good shape of it.

The material used to make the nozzle is something else really important to consider. Common materials for nozzles include ceramic, tungsten carbide, and boron carbide. These are popular for their high durability. They do not break at high temperatures and under pressure. When selecting a nozzle, consider what you’re cleaning and ensure that the nozzle is appropriate for that particular task.

Wearing quality shot blasting nozzles can truly improve your cleaning assignment remarkably productive. As an example, Longfa shot blasting nozzles are specially developed to save air and waste less shot during cleaning. This not only saves time and money but means you don’t also have to refill the shot. That both makes your cleaning process more efficient and maximizes the longevity of the nozzle.

The second advantage high-speed shot blasting nozzles offer is a relatively rougher surface profile. That roughness is useful, because it helps new coatings stick. Surfaces that are cleaned correctly are prepared for the next step in the process, either painting or a coating of a different kind. The Longfa shotblaster can make the cleaning really fast and effective, which is why they are really important tools in different industries like construction, shipbuilding, and manufacturing.

There is a wide range of materials and types of shot blasting nozzles, each type having its own distinct benefits. Table: "Easier and Cheaper" We know that ceramic nozzles are good and cheap, because they are easier to use, and expensive ones can easily break down during use, such as ceramic nozzles, which are often used to add something, or at high temperatures, they are easy to cause melting. Tungsten carbide and boron carbide nozzles are costlier, but they are also long-lasting. Higher temperature and pressure resistant, so less failure in harsh service.

Depending on the applications’ purpose Longfa’s shot blasting nozzles can be manufactured from different materials. These include tungsten carbide, boron carbide, ceramic, and metal. Each material is selected to maximize performance for various cleaning needs. A nozzle design plays a key role as well since it will not only influence the speed but can also change the way a shot is released. The design of the shot blaster media dictates the discharge pattern, the velocity, and the efficiency of the shot. Longfa’s nozzles are engineered for performance and efficiency.

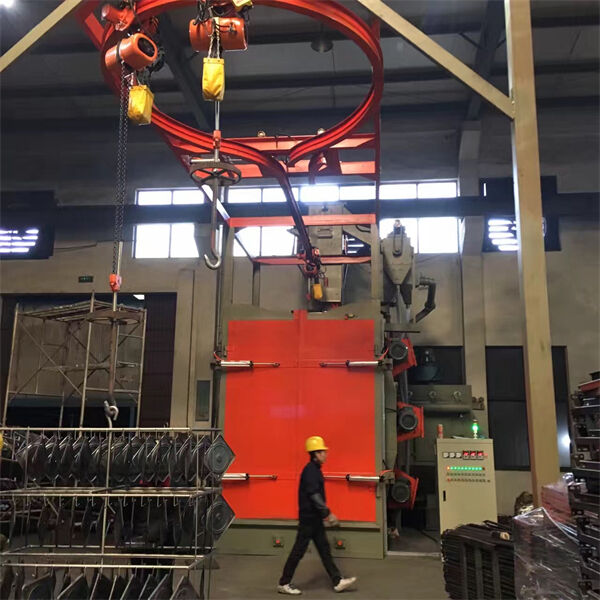

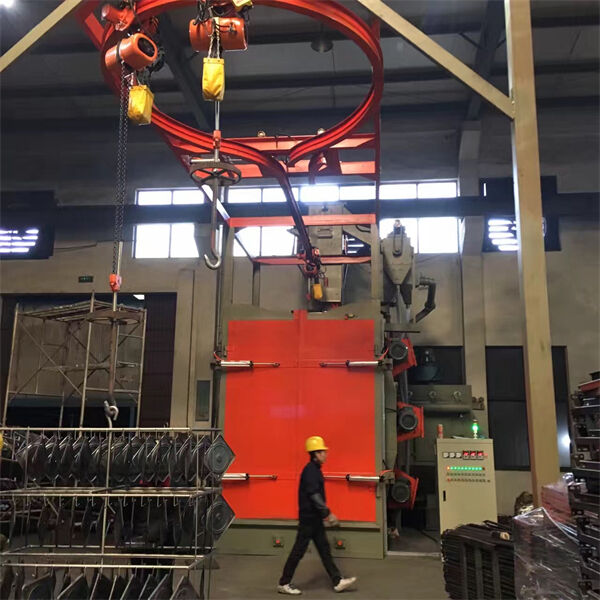

The company's main activity is the production of ball cleaning equipment and other accessories for Shot blasting nozzles. We offer a broad range of products including shotblasting machines, large coil shotblasting machines, wind power tower shotblasting machines and blasting of the outer wall of steel pipe machines, and other shotblasting machines.

Longfa is a manufacturing facility with a total area of 80,000 square metres and an RD center of 20000 square meters. Longfa has Shot blasting nozzles with more than 40 models, in addition to over 200 different kinds of spare components and accessories that can meet every customer's requirements in full terms. The registered capital of 60 million yuan is worth more than $100 million per year.

The company has been certified by Shot blasting nozzles as well as CE. It also has over 40 patents. This includes our shot blasting equipment that are protected by exclusive intellectual property rights. It was designated as an enterprise with high-tech capabilities in Jiangsu, a province.

In the Shot blasting nozzles of manufacturing, the shot blasting equipment can be utilized in ship rust removal, steel structure rust removal in spray pretreatment and more. More than 2000 clients are supported by this business and they export to more than 60 countries.