- סקירה כללית

- מוצרים קשורים

מספר דגם | Q6910 | Q6920 | Q6925 | Q6930 | Q6940 | Q6950 |

גודל ניקוי (mm) אורךxרוחב | 12000 (L) x1000 (W) עבה: 6-60H: 500 | 12000 (א) X 2500 (ר) עובי: 6-60 H: 400 | 12000 (אורך) X 2500(רוחב) עבה: 6-25 H: 400 | 12000 (א) X 3000 (ר) עובי: 6-60 H: 400 | 12000 (א) X 4000 (ר) עבה: 6-60 H: 400 | 12000 (א) X 5000 (ר) עבה: 6-60 H: 400 |

מהירות הרצת שולחן גלגלים (מ'/דקה) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

אורך גלגלת התזונה (מ"מ) | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

רוחב עבודה יעיל (מ"מ) | 1300 | 2300 | 2800 | 3300 | 4300 | 5300 |

אורך גלגלת השחרור (מ"מ) | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

עוצמת מפוח הסילוק של אבק (kw) | 15 | 18.5 | 22 | 37 | 45 | 55 |

מספר מכשירי הזרקת כדור (טאיוואן) | 4 | 6 | 6 | 8 | 10 | 10 |

עוצמת זריקה בכדורים (kw) | 11X4 | 15X6 | 18.5X6 | 22X8 | 22X10 | 30X10 |

כמות שפיכת כדור (קג/דקה) | 250X4 | 270X6 | 290X6 | 340X8 | 340X10 | 400X10 |

עוצמת מעלית (kw) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

כליית העלאה (ט/ש) | 60 | 90 | 140 | 180 | 225 | 260 |

עוצמה של מפריד (ק"ו) | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 |

ขนาด המנה המופרדת (ט/ש) | 60 | 90 | 144 | 120 | 170 | 170 |

עוצמה גROSS (ק"ו) | ≈86 | ≈153 | ≈189 | ≈280 | ≈350 | ≈454 |

חברת ג'יאנגסו לונגפא לבקרות פליטה בע"מ

1. איך להתקין את המכונה? ציוד מלא של מכונת קיטוף פלדה, ציוד סטנדרטי יכול לבחור התקנה מרחוק מודרכת. נסדר 1-2 מהנדסים להדריך את ההתקנה והאספה של ציוד לא-סטנדרטי במפעל שלכם

2. האם אתם מוכרים כדורות פלדה או חול פלדה שניתן להשתמש בהם במכונת שוט בלסטינג? אנו יכולים לספק מוצרים כמו כדורי פלדה, חול פלדה, כדורי חיתוך תיל פלדה, כדורי פלדה ללא גיר, ואבזרים מתכתיים אחרים הקשורים לטיהור פני השטח ומניעת קרוש

3. כמה זמן לוקח לכם לספק? בדרך כלל, זמן ייצור למכונה סטנדרטית של טיפוח כדור הוא 7-20 ימי עבודה. למכונה לא סטנדרטית של טיפוח כדור זה 20-60 ימי עבודה. זמן ייצור למכינת פליטת כדורים הוא 30-60 ימי עבודה. זה תלוי בכמות ובטיפוס המכונה.

4. מהי מכונת שוט בלסטינג? טיפוח כדורים הוא שיטה המשמשת להטיהור, לחיזוק (פליטה) או לפוליש מתכת. טיפוח כדורים משמש כמעט בכל תעשייה המשתמשת במתכת, כולל תעופה, אוטומובילים, בניין, יציקה, בניית אוניות, מסילות רכבת, ועוד.

5. מהן שירותיך לפני מכירה ואחרי מכירה? שירותים לפני מכירה כוללים: ייעוץ מוצרים, דגימות, פתרונות טכניים והצעות מחיר; שירות לאחר מכירה כולל: תגובה של 24 שעות, הנחיות מקוונות של מהנדסים, התקנה של מהנדסים במפעל הלקוח, ובידוד כיצד להתקין ולהשתמש המוצר

Longfa

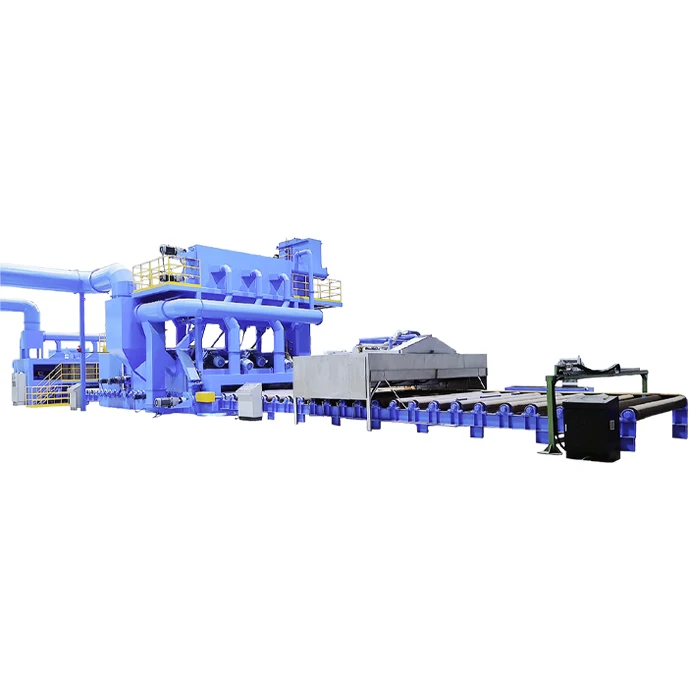

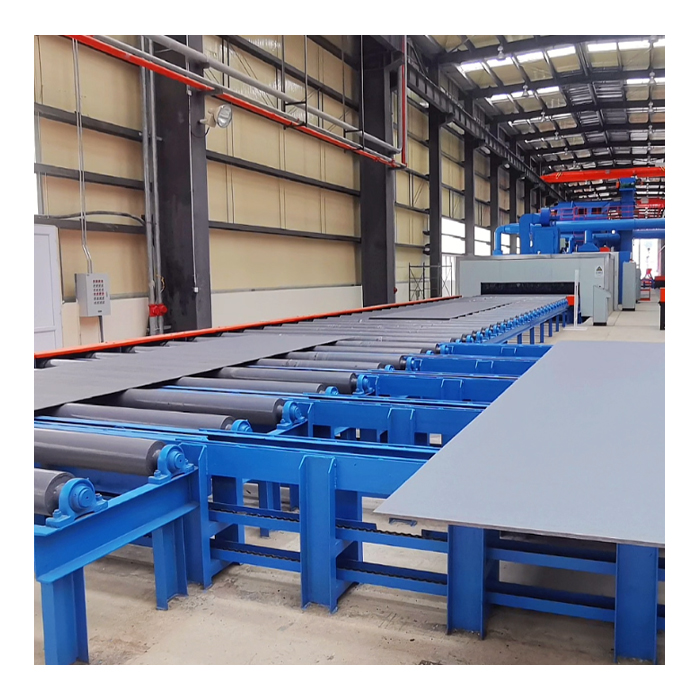

הכרזה על טכנולוגיה חדשה למכונה לשפigtת פלדה בעיבוד תעשייתי. פתרון נוח ויעיל לצרכי הכנת הפנים של הפלדה שלך. משתמש בגלגל שיגור מהיר כדי להטיל כדוריות על לוחות מתכת ולהסיר כל זיהום או רזיד מפניה, מה שמצרף אותו לטיהור והכנה לתסיסה או לעיצוב. עשוי מ质erials עליונים, המחשב הזה הוא אמיץ ומתוכנן לעמוד בשימוש כבד בתעשייה. קל להפעלה עם שליטה ידנית אינטואיטיבית שמאפשרת לך להתאים את עוצמת השפigtת לפי הצורך שלך. מאופטם לבטיחות עם כיסויים מגינים למניעת תאונות ובטיחות עובדים. מושלם לייצור מסחרי בהיקף גדול עם תכולה של עד 3000 מ"מ ברוחב הלוח ו-100 מ"מ בגובהו. הוא יכול לבצע שפigtת של עד 280 מטרים מרובעים של לוח מתכת בשעה, מה שגורם לו להיות פתרון יעיל במיוחד עבור פעולות כמותיות גבוהות. ידידותי לסביבה. משתמש בכדוריות במקום תהליך סנדהייזינג שעשוי לגרום להפרשות אבק מסוכנות. מגיע עם מערכת איסוף אבק שמבטיחה סביבה נקייה וחסרת אבק. קניית זה תסייע לusahaan שלך לחסוך בזמן להפחית את עלויות העבודה. משמידה את הצורך בשיפוץ ידני. עם תוצאות אחידות וקבועות, השפigtת גם תסייע לשפר את איכות התוצר שלך, עם הגנה אחידה ובטחת ארוכת טווח נגד רזיד וקרוסיו. קנו זאת היום וחויבו חוויה ללא תקלה כמו שלא היה לכם בעבר.