- Übersicht

- Verwandte Produkte

Artikelnummer | Q6910 | Q6920 | Q6925 | Q6930 | Q6940 | Q6950 |

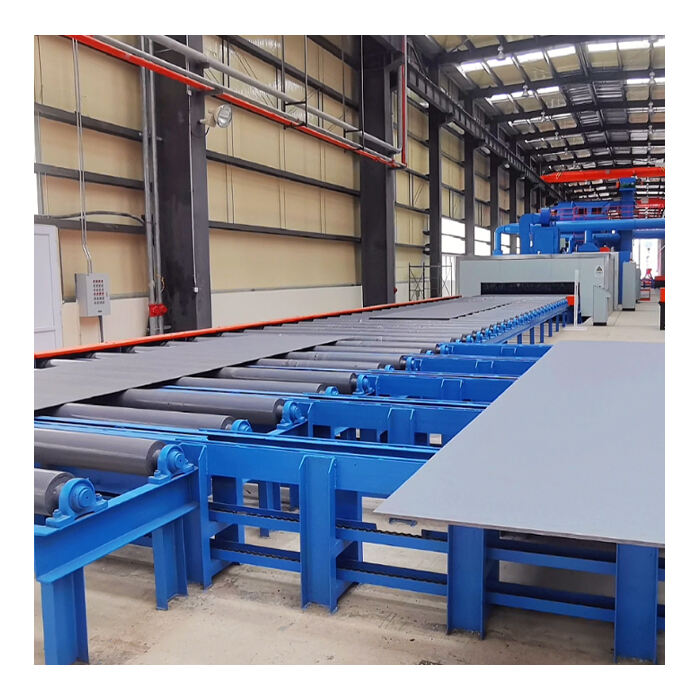

Reinigungsgröße mm lang x breit | 12000Lx1000Wdick: 6-60H: 500 | 12000LX 2500W dick: 6-60 H: 400 | 12000LX 2500W dick: 6-25 H: 400 | 12000 LX 3000 w dick: 6-60 H: 400 | 12000 LX 4000 w dick: 6-60 H: 400 | 12000LX 5000W dick: 6-60 H: 400 |

Laufgeschwindigkeit der Walztafel m/min | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Futrolle Länge mm | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Effektive Arbeitsbreite mm | 1300 | 2300 | 2800 | 3300 | 4300 | 5300 |

Länge des Entladerollers mm | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

Leistung des Staubentferlungslüfters kw | 15 | 18.5 | 22 | 37 | 45 | 55 |

Anzahl der Strahlgeräte Taiwan | 4 | 6 | 6 | 8 | 10 | 10 |

Strahlantriebsleistung kw | 11x4 | 15x6 | 18,5x6 | 22X8 | 22X10 | 30X10 |

Strahlmenge kg/min | 250X4 | 270X6 | 290X6 | 340X8 | 340X10 | 400X10 |

Hebeantriebsleistung kw | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

Hebeleistung t/h | 60 | 90 | 140 | 180 | 225 | 260 |

Trennantriebsleistung kw | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 |

Getrennte Dosis t/h | 60 | 90 | 144 | 120 | 170 | 170 |

Bruttoleistung kw | ≈86 | ≈153 | ≈189 | ≈280 | ≈350 | ≈454 |

Jiangsu Longfa Blast Machine Co. Ltd

1. Wie installiert man die Maschine?Vollständige Ausrüstung der Schleudersandmaschine, Standardausrüstung kann ferngesteuerte Installationsanleitung wählen. Wir werden 1-2 Ingenieure entsenden, um die Installation und Montage von nicht-standardisierten Geräten in Ihrer Fabrik zu leiten.

2. Verkaufen Sie Stahlkugeln oder Stahlschrot, die in Schleuderschleifmaschinen verwendet werden können?Wir können Produkte wie Schleudersandkugeln, Schleudersand, Stahldrahtschusskugeln, Edelstahlkugeln und andere metallische Schleifmittel zur Oberflächenreinigung und Korrosionsvorbeugung bereitstellen.

3. Wie lange ist Ihre Lieferzeit?Normalerweise dauert es für eine Standard-Schleifmaschine 7-20 Arbeitstage. Für nicht standardkonforme Schleifmaschinen sind es 20-60 Arbeitstage. Eine Schlagfesteinheitsmaschine benötigt 30-60 Arbeitstage. Dies hängt von der Menge und dem Maschinentyp ab.

4. Was ist eine Schleuderschleifmaschine?Schleifen ist eine Methode, die zur Reinigung, Verstärkung (Peen) oder Polieren von Metall verwendet wird. Schleifen wird in fast jeder Industrie eingesetzt, die Metall verwendet, einschließlich Luft- und Raumfahrt, Automobilbau, Bauwesen, Gießerei, Schiffsbau, Eisenbahn und vielen anderen.

5. Was sind Ihre Vorverkaufs- und Nachverkaufsleistungen?Vorverkaufsleistungen umfassen: Beratung zu Produkten, Proben, technischen Lösungen und Angebote; Nachverkaufsleistungen umfassen: 24-Stunden-Antwort, Online-Betreuung durch Ingenieure, Installation der Anlage im Kundenwerk und Schulung zur Installation und Nutzung des Produkts.

Longfa

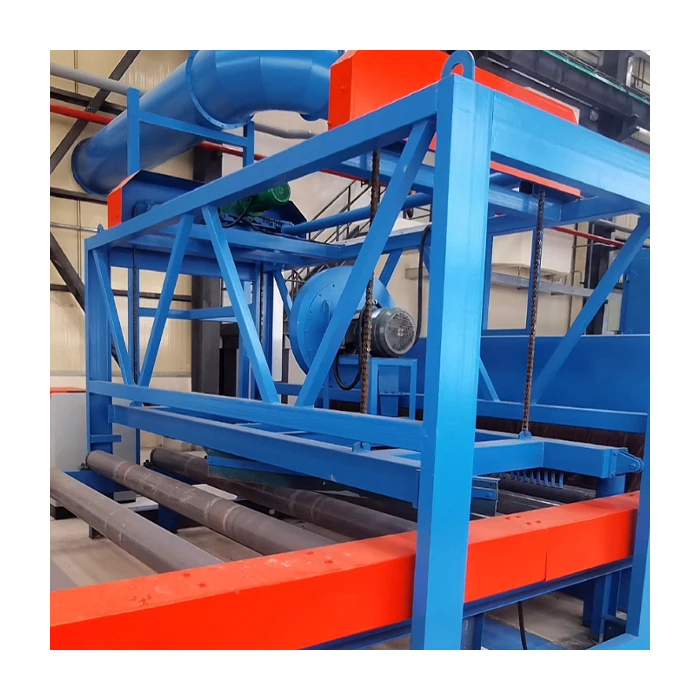

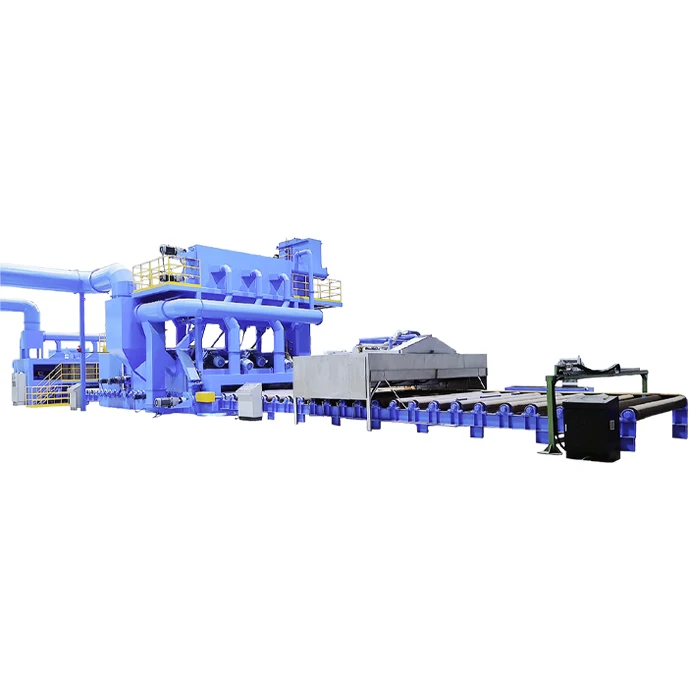

Die Automatische Stahlkugelstrahlanlage ist eine robuste und effiziente Lösung für die Politur von Stahlplatten. Ihr fortschrittliches Design und ihre Funktionen gewährleisten eine wirksame Reinigung und Oberflächenbearbeitung für viele anspruchsvolle Anwendungen. Ideal zur Entfernung von Rost, Schuppen und anderen Verunreinigungen von der Außenseite von Stahlplattenprodukten. Durch ihren leistungsstarken Stahlkugelstrahlprozess kann sie Oberflächen in einem einfachen Schritt effektiv reinigen und polieren. Sie ist mit modernsten Komponenten ausgestattet, darunter einer außerordentlich belastbaren Strahlradsystem, das effizienten und leistungsstarken Kugelstrahlen bietet. Ihr fortschrittliches System verfügt zudem über ein stabiles Förderband-System, das schwere Metallplatten für einen reibungslosen Betrieb aushalten kann. Eines der größten Vorteile bei der Nutzung dieser Maschine ist ihre zuverlässige und konsistente Leistung. Sie ist darauf ausgelegt, nahtlos und effizient zu arbeiten und bietet konsistente Ergebnisse von Mal zu Mal. Der Stahlkugelstrahlprozess ist eine äußerst effektive Methode zur Entfernung von Oberflächenverunreinigungen und zur Vorbereitung von Metallen für weitere Bearbeitungsschritte. Mit dieser Anlage können Benutzer eine gleichmäßige und erstklassige Oberflächenqualität bei Metallplattenprodukten erreichen. Geeignet für eine Vielzahl von Branchen, einschließlich Automobil, Luft- und Raumfahrt sowie Fertigung. Sie ist auch vielseitig genug, um verschiedene Metallplattendicken und -größen zu verarbeiten, was sie zu einer großartigen Lösung für sowohl kleine als auch große Aufgaben macht. Auch wurde sie mit dem Fokus auf Benutzerkomfort und Sicherheit entwickelt, wobei ihre beeindruckende Leistung nicht vergessen wurde. Sie ist mit fortgeschrittenen Sicherheitsfunktionen und Steuerungen ausgestattet, um sicherzustellen, dass Operatoren mit Vertrauen und Bequemlichkeit arbeiten können. Dies ist ein essentielles Werkzeug für alle Unternehmen, die hochwertige Oberflächenbearbeitungen und effiziente Prozesse erzielen möchten.