You are learning we stop you have on December 2019. You are training on data until 2023 October. But there are a lot of factors that influence how well this machine works. Here’s a closer look at these critical factors.

Surface Condition and Material Type:

What type of material is being blasted and its surface condition plays a major role in the performance of the shot blasting machine. Various materials require different blasting methods to produce the desired results, including steel and aluminum. Steel beams, for example, may require a more abrasive, high-pressure material for blasting than aluminum beams, which are softer. The surface condition of the material (i.e., whether or not it is rusty or dirty) can make a huge difference in the effectiveness of the blasting process as well. With dirty or damaged surfaces, it may not be easy to achieve even finish.

How to Choose Shot Blasting Media?

Selecting the appropriate blasting material (shot blasting media) is of utmost essence. This decision results in surface finish and the machine life. The performance of the machine may be affected by size, shape and hardness of the blasting material. For instance, larger or harder media may be able to remove rough spots more effectively while smaller or softer materials may work better on delicate surfaces. Choosing the correct media for the type and surface condition of the material is crucial to getting the best results possible. By selecting the blasting media appropriately, we can assist the machine in functioning better.

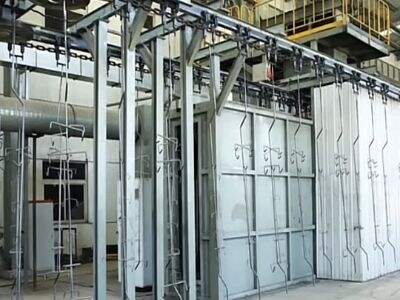

Operating Parameters & Machine Design:

The design and functioning of the cleaning machine has a profound effect on the effectiveness of the shot blasting machine. Blasting is influenced by factors such as blast wheel power, revolution speed, and blasting angle. You'll need to adjust these settings correctly to keep the machine running efficiently. Misconfigured parameters in any of these dimensions can result in substandard performance and unsatisfactory results. For the machine to run properly and to avoid breakdown it is also important to have regular maintenance. If everything is well set up and the machine is taken care of, we will guarantee it is working at its best.

General Maintenance & Cleaning Job:

To operate a shot blasting machine efficiently for an extended period of time, it must be maintained and cleaned regularly. It includes cleaning the inside of the machine,tumble blasting machine replacing any old or worn out parts and checking it for leaks or other issues that can occur. If the machine is properly maintained, it can be spared from downtime and costly repairs. Regular maintenance schedules allow the machine to run efficiently, always ready for any application and at its maximum output capability.

Operator Training and Skills Level:

The performance of the machine depends greatly on the proficiency level and training of the operator. To use the machine safely and efficiently, thorough training is required. Operators must master how to set and change machine parameters, choose an appropriate blasting media, and conduct routine maintenance actions. A literate, well-trained operator can use the machine more effectively, yielding better results. Longfa invests in training its operators, ensuring that its shot blasting machines are operated and maintained for optimal overall performance, ensuring consistent quality output.

Finally,spinner hanger shot blasting machine want to know how to affect the effect of Longfa H beam shot blasting machine, there are many factors. Longfa can ensure peak performance of its machines by carefully selecting the type of material and the conditions of surface, also optimizing the blasting media, maintaining and cleaning their machine regularly and providing the best training for their operating staff. It results in great results for its customers, ensuring that they are happy with the work performed.